High & Low Temperature Series

Rapid Temperature Change Test Chamber

Rapid Temperature Change Test Chamber

Features

• R404A and R23 environmentally friendly refrigerants with zero ozone damage are used.

• All pipeline welding is protected by nitrogen gas to ensure that the inside of the pipeline is not oxidized, and the surface of welding joint and pipeline is coated with anti-corrosion protective layer.

• Using intelligent microcomputer PID+SSR and FUZZY control, the control accuracy is stable and precise, which can fully meet customer test requirements.

• The multi-blade blower is used for strong air circulation to avoid any dead angle and ensure uniform distribution of indoor temperature and humidity.

• The box circuit system, water system and refrigeration system are modularly distributed to ensure safe and reliable operation.

Applicable Standards

Chinese standard

GB/T2423.1-2008 Environmental Testing of Electrical and Electronic Products Part 2: Test A: Low Temperature Test Method

GB/T2423.2-2008 Environmental Testing of Electrical and Electronic Products Part 2: Test B: High Temperature Test Method

GB/T2423.3-2016 Environmental testing of electrical and electronic products Part 2: Test Cab: Constant damp heat test method

GB/T2423.4-2008 Environmental test of electrical and electronic products Part 2: Test Db: Test method for alternating damp heat

GJB150.3A-2009 Laboratory Environmental Test Methods for Military Equipment Part 3: High Temperature Test

GJB150.4A-2009 Laboratory Environmental Test Methods for Military Equipment Part 4: Low Temperature Test

GJB150.9A-2009 Laboratory Environmental Test Methods for Military Equipment Part 9: Damp heat test

International standard

IEC 60068-2-1:2007 "Environmental Testing Part 2-1: Tests Test A: Low Temperature" (English version)

IEC 60068-2-2:2007 "Environmental Testing Part 2-2: Test Test B: Dry Heat" (English version)

IEC 60068-2-78:2012 "Environmental Testing Part 2-78: Tests Test Cab: Constant Damp Heat Test" (English version)

IEC 60068-2-30:2005 "Environmental Testing Part 2-30: Test Test Db: Alternating Damp Heat Test" (English version)

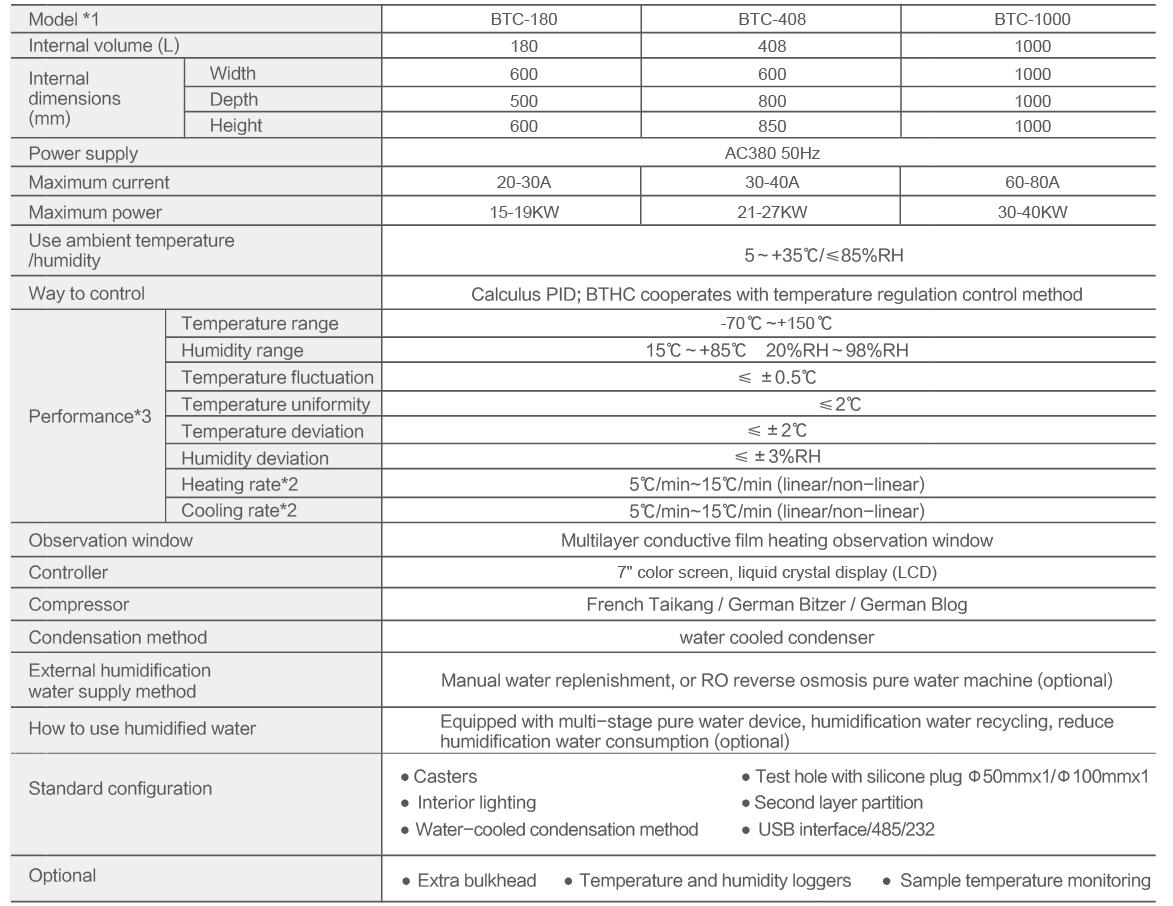

Specification & Technical Data

*1: Humidity control function according to customer requirements;

*2: Average rate between maximum temperature and minimum temperature (no load, no heat dissipation, refer to IEC60068-3-5);

*3: The performance index is measured when the room temperature is +25°C, and the sensor is located at the air outlet of the air handling unit.

Note: 1. The above contents are subject to change without notice.

2. According to customer requirements, other non-standard size rapid temperature change test chambers can be

customized.