High & Low Temperature Series

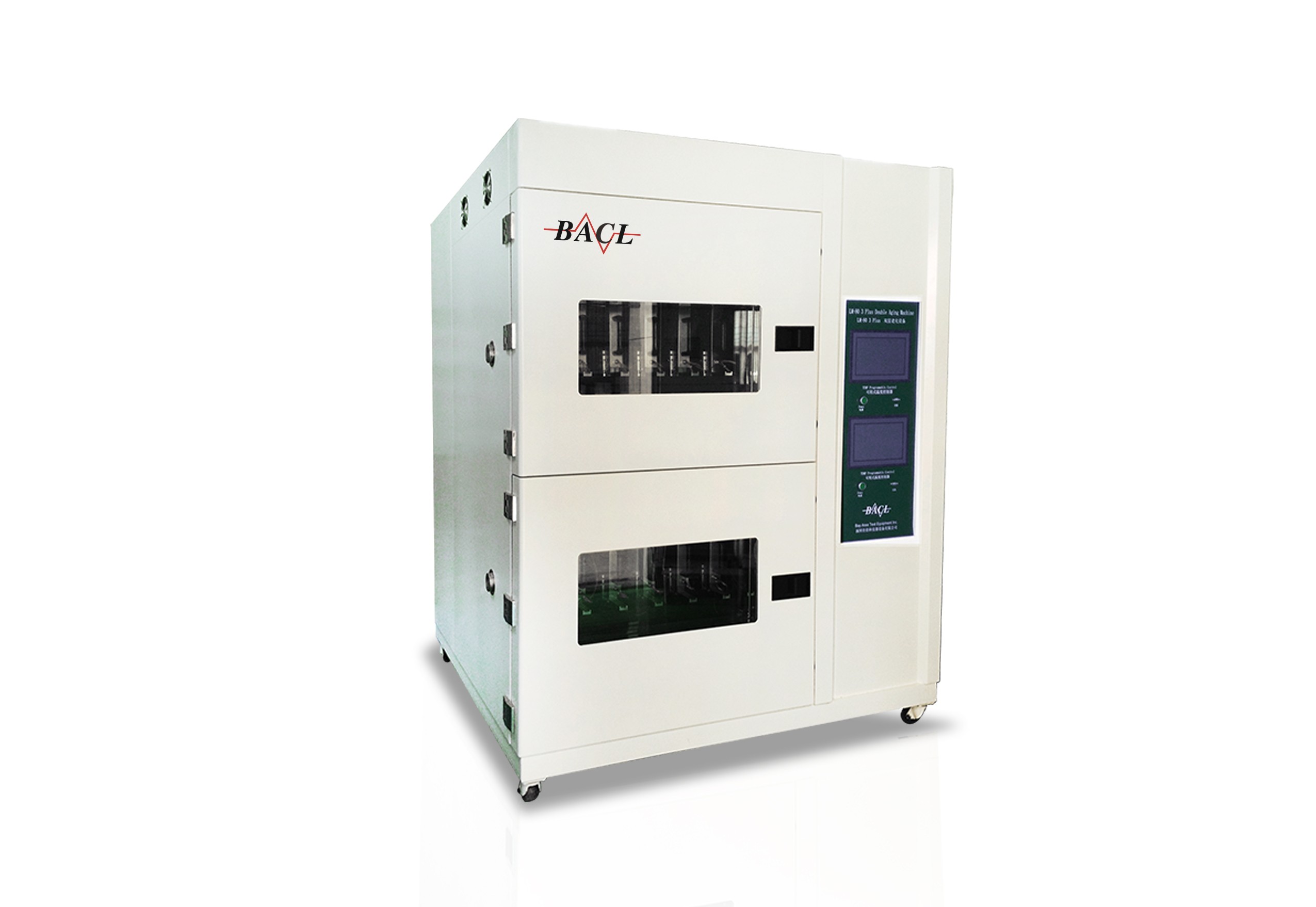

3rd Generation LM-80 B3-Plus Semiconductor Cooling Aging Equipment

3rd Generation LM-80 B3-Plus Semiconductor Cooling

Aging Equipment

Features

• It is an upgrade and improvement on the basis of three generations of patented product technology.

• Especially designed for high-power COB and integrated PCB solutions, the maximum power of a single product supports 800W.

• Semiconductor + water cooling temperature control technology, 10 independent refrigeration modules, accurate and effective temperature control of Ts and Ta.

• Support PCB gold finger power-on scheme, the product is simple and safe to power on.

• Support integrating sphere online test system, directly connect with optical and speed test system.

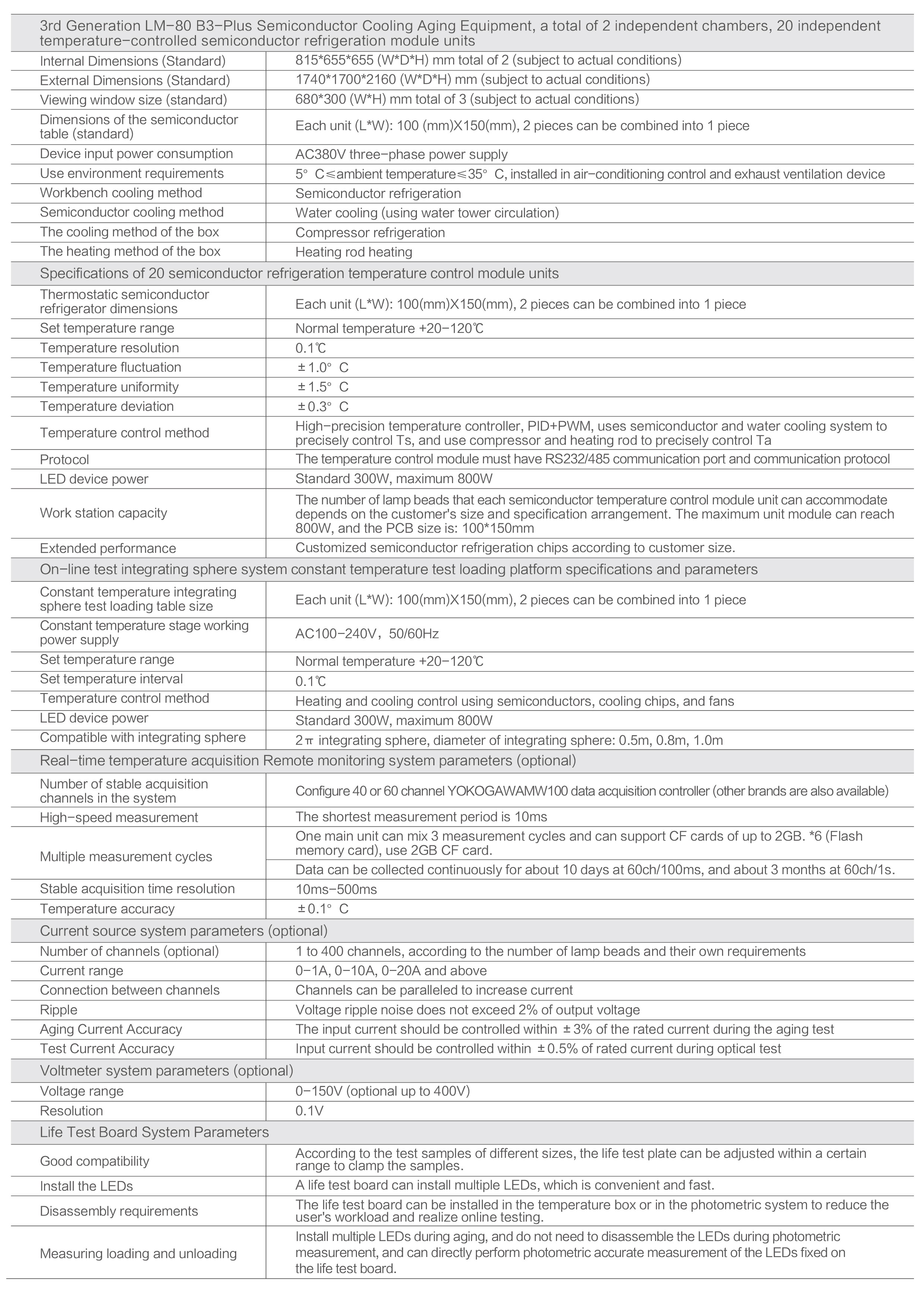

Specification & Technical Data